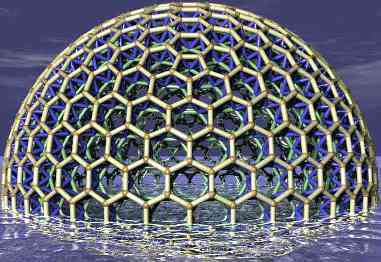

HexDome

Tube Loop Tensegrities

Tube Loop Tensegrity

|

Tube Loop Tensegrities

Previously, constructing tensegrities has typically involved

making grooves in the end of struts, or drilling holes in

the ends of them.

This can generate some problems:

- The poles extended beyond the end of the cables -

resulting an protruding sharp edges which tend to penetrate

any covering material;

- Holes and grooves in metal tubes tend to need deburring

if they are not to cause cables to fray.

- Drilling holes or sawing grooves increases construction

costs;

- Drilling holes or sawing grooves damages the strut

material - and generates local weak points;

Here we present a method of constructing tensegrities

using struts that are unadulterated tubes, with no

need for the cutting of grooves, or drilling of holes.

The methdod is pretty simple - it's illustrated in the diagram

above.

Each strut has one or more cables running down its middle.

Each cable passes through two or more struts.

Problems

The model illustatated was constructed using wire and PVC.

The stiffness in the wire makes it difficult to tell how

this particular model would behave if everything was

perfectly frictionless. However in theory some models

without friction will still retain their structural

integrity.

In practice a number of measures could be taken to prevent

motion of individual cables in the tubes if that proves

necessary - including steps such as twisting the cables

inside the tubes together, and inserting dowels into the

ends of the tubes.

This modelling technique typically results in increased

expenditure on cables. You can often avoid having more than

two cables running through each strut, though - once you

have two cables, others can usually be looped around them or

tied to them.

Tim Tyler |

Contact |

http://hexdome.com/

|